CENTRE FOR EFFICIENT PRODUCTION

The Centre for Efficient Production (CEPR LLC) was established in 2010 aimed to introduce on the Russian market advanced solutions and systems for increasing the useful life of high-tech production equipment that have already proven themselves in the European and global industry.

Today, CEPR is a group of companies that provides solutions for the maintenance of metalworking equipment using modern approaches and tools. CEPR has established its own repair production of spindle units and manufacturing of precision machine tool components. A specialized division was organized in order to develop and implement innovative solutions for equipment monitoring and protection.

Thanks to a representative portfolio of successfully completed orders and established professional cooperation with the world's leading manufacturers of machine tools and machine tool components, CEPR Group has gained a reputation of a reliable partner in the country's mechanical engineering business.

Service

Solutions 4.0

AUTOMATED COOLANT MONITORING

The ACM 4.0 coolant quality control system, in fact, solves the problem of “unmanned” reliable coolant maintenance, significantly reducing consumption, saving operators, machine and workpiece from negative influences with a guaranteed high result.

Learn moreMACHINE PROTECTION

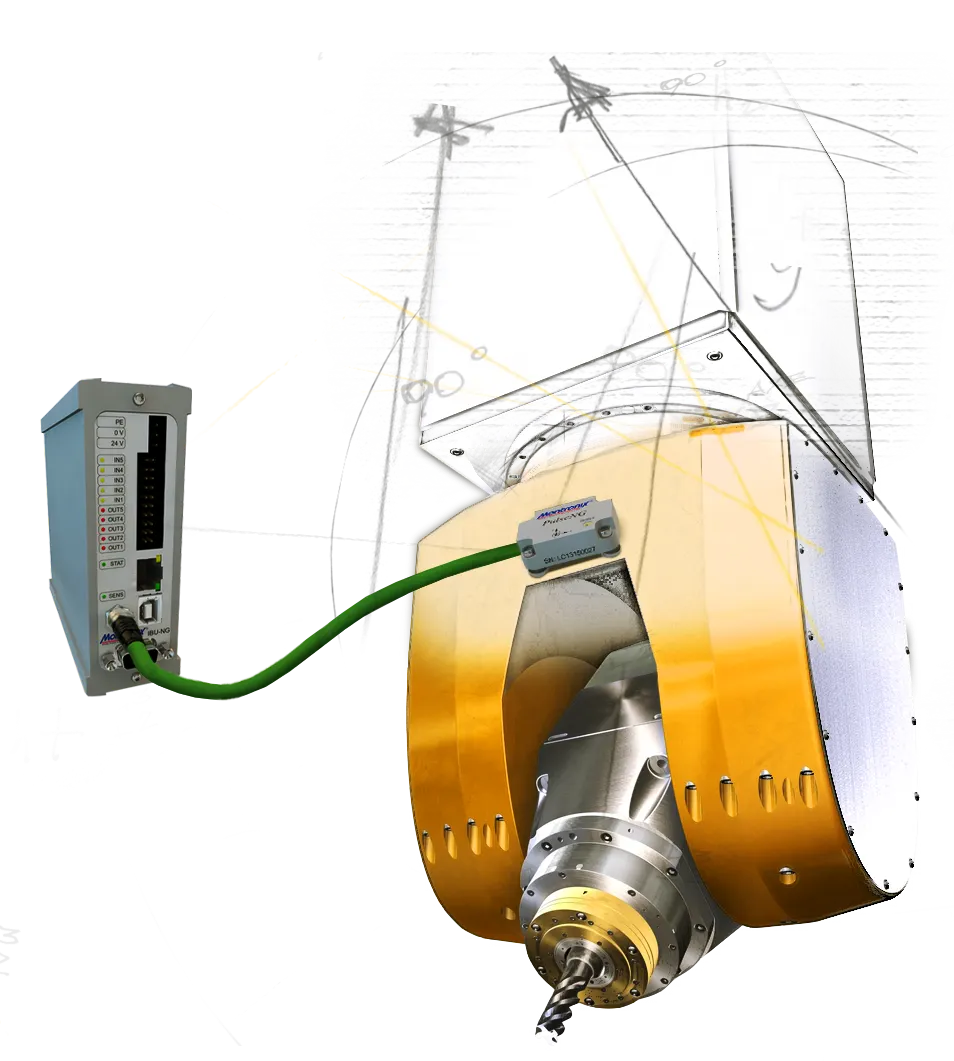

The machine equipment monitoring system based on the Montronix platform allows the observation of correct operating modes, prevents critical overloads on components and mechanisms, minimizes the consequences of emergencies, and performs operational in-place diagnostics of equipment.

MACHINE

SERVICE

The INMASHSERVICE company was established in 2016 as a part of CEPR Group with the aim of providing high-quality machine service to ensure the continuous operation of the equipment and the maximum efficiency of your production.

Our engineers are proven experts with many years of successful high-quality work for leading Russian customer enterprises, applying their expert knowledge of equipment, processes and analytics, backed up by internships and training from leading foreign machine tool builders.

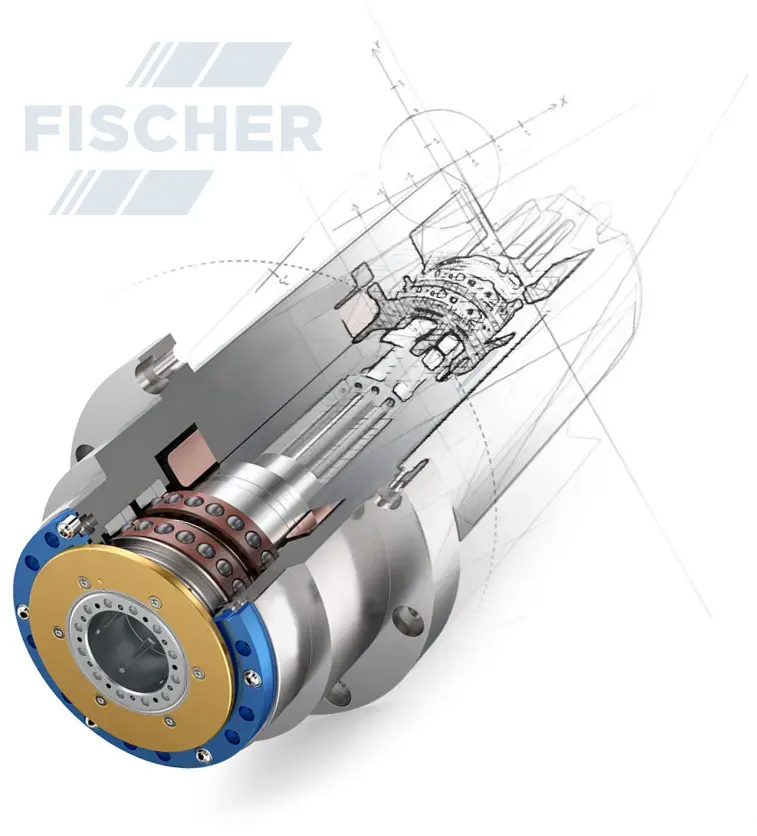

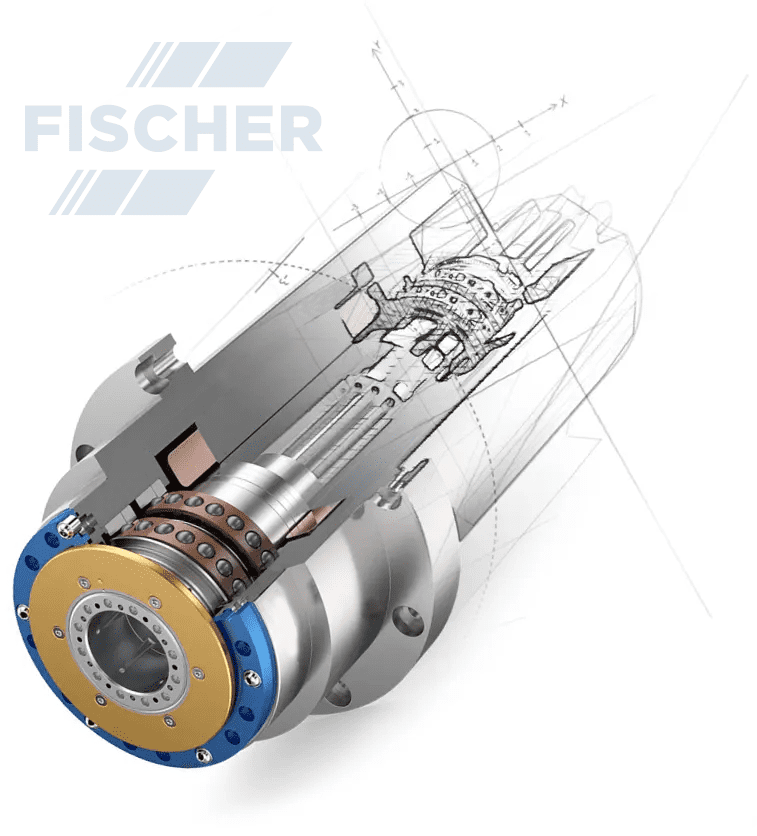

SPINDLES AND MILLING

HEADS REPAIR

Fischer Spindel Technology was established in 2010 with the aim of organizing a high-tech service centre for the repair and maintenance of motor spindles for Russian machine-building plants. The co-founder of the company was the Swiss industrial group FISCHER Spindle Group AG, one of the world's leading manufacturers of spindle assemblies. It allowed the Russian joint venture to obtain and quickly implement advanced technologies for servicing at the highest level. For many years, the company has been the leader in the spindles and milling heads repair on the Russian market.

CONTINUOUS

DEVELOPMENT

As part of the ongoing development, we established an innovative product development department in order to automate the equipment maintenance. Led by experienced mechanical engineers, our young and ambitious team researches, develops and implements our own solutions thus increasing the availiability and efficiency of domestic production.

NEWS

OUR PARTNERS

Contacts

Contact us